Products

Applications

Learning

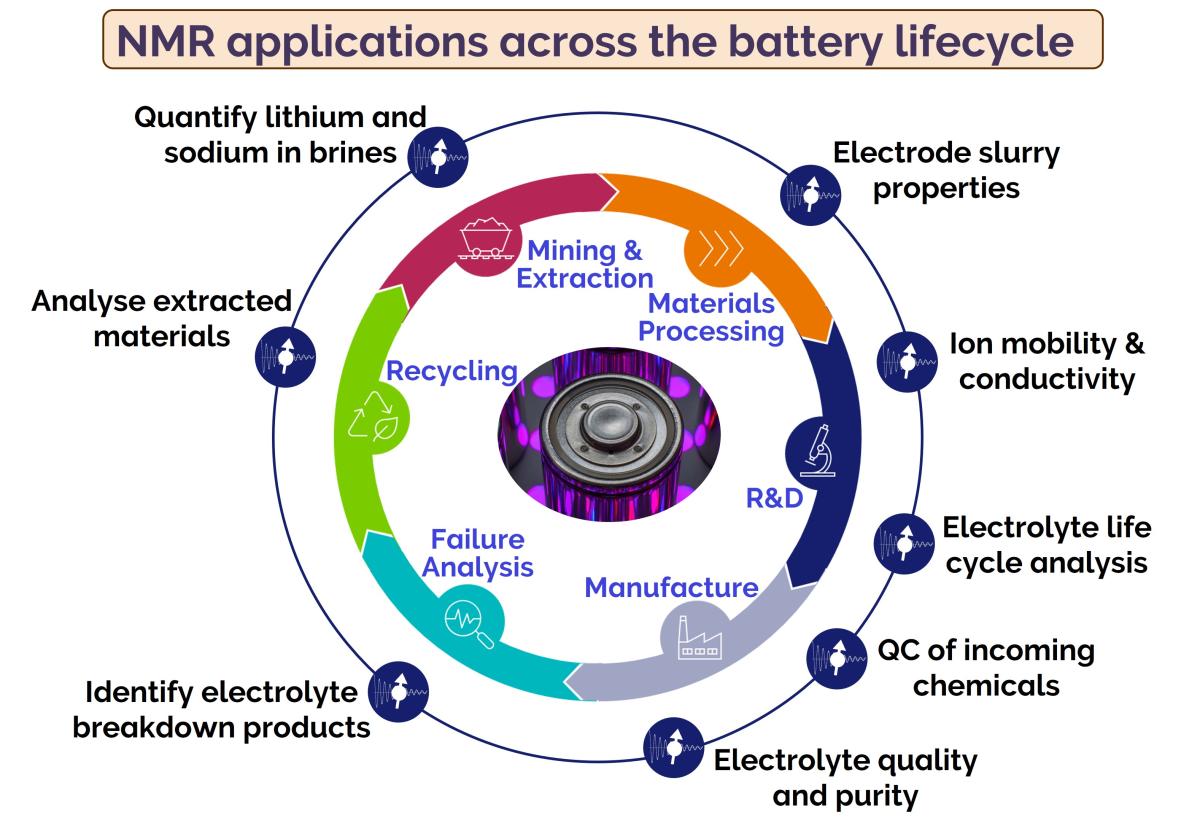

China is the largest manufacturer of lithium-ion batteries. Current carrying electrolytes drive both improvements in battery performance and lifetime. Recently, broadband benchtop NMR has become a key characterisation tool for lithium battery electrolytes. Dr Elvis Wen from Oxford Instruments NMR applications team joined China’s 2nd National Lithium-ion Battery Electrolyte Symposium at Changzhou in August 2023. Elvis presented NMR spectroscopy data he has carried out to support electrolyte manufacturers, battery suppliers and University researchers. Elvis also networked extensively with the community. We asked him to share his personal experiences from the event.

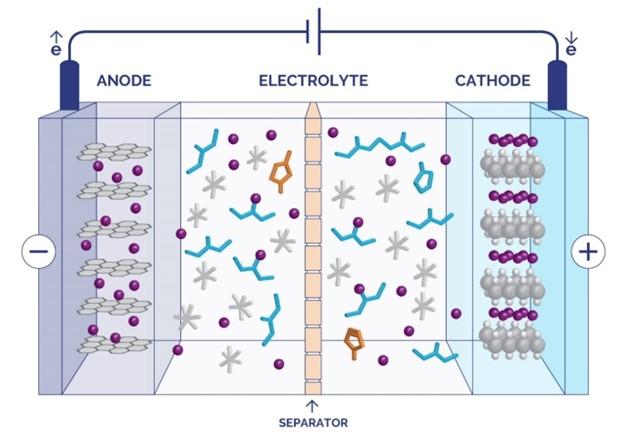

As one of the four key main battery materials, the electrolyte links all components in the battery and transfers current carrying lithium ions between positive and negative electrodes. It significantly impacts lithium-ion batteries including performance at high and low temperatures, their charging rate, the energy density (power) and their full lifetime safety. Therefore, with the intensive research focus on lithium-ion battery technology and battery materials analysis, the role of electrolytes is increasingly being targeted by researchers, process engineers and across quality control.

Schematic diagram of a lithium battery: the electrolyte solvents, lithium salts and additives all impact performance and lifetime

Lithium-ion batteries play a crucial role in the blueprint for sustainable and rapid development in China. With our commitment to become carbon neutral by 2060, there is a higher and more urgent demand for large-scale energy storage batteries supporting new energy. There is also an critical need for safe, longer lasting and higher power batteries because the number of electric vehicles and electric bicycles in China has already reached 5 million and 300 million, respectively, and continues to grow rapidly.

This symposium attracted researchers across universities, electrolyte manufacturers and China’s leading battery suppliers. The focus on advanced lithium-ion battery electrolyte technologies included:

In recent years, significant progress on electrolyte innovation has been made in both core scientific research in academia and industry, and many young and top-notch talents have emerged. This symposium was a bridge that connected the supply chain upstream and downstream, and a networking forum for pioneering scientists. I was inspired to present my nmr spectroscopy data at the symposium and contribute in the drive to continuously promote the technological progress of lithium-ion batteries in China.

Several topics were particularly interesting for me because I want to help with nmr analysis of battery electrolytes our customers who supply the chemicals, the electrolyte manufacturers, as well as China’s battery suppliers:

1. New materials for electrolytes such as new solvents, lithium salts, and additives

2. Advanced characterization methods for basic science of electrolytes

3. Research progress in new lithium-based battery electrolytes

4. Application of artificial intelligence in electrolytes

5. The wider development trends in electrolyte and battery industry

The most common techniques being used for battery electrolyte analysis by the conference delegates included NMR Spectroscopy, Raman Spectroscopy, Infra-red Spectroscopy, Density Function Theory (DFT) analysis and electrochemistry methods such as voltammetry.

Yes, very much so - it was appreciated that NMR is an inherently quantitative method for lithium-ion battery characterisation that not only identifies the components within electrolytes but also provides information about their diffusion, conductivity properties and root causes of failure. Several delegates commented that it was:

1. A powerful technique for lithium solvation characterization

2. A stable method for diffusion measurement which can significantly decrease the artificial interference compared to electrochemical methods

3. The broadband capabilities of the X-Pulse instrument in particular were seen as really valuable for comprehensive analysis because you quickly measure all the components within the electrolyte system in a single instrument

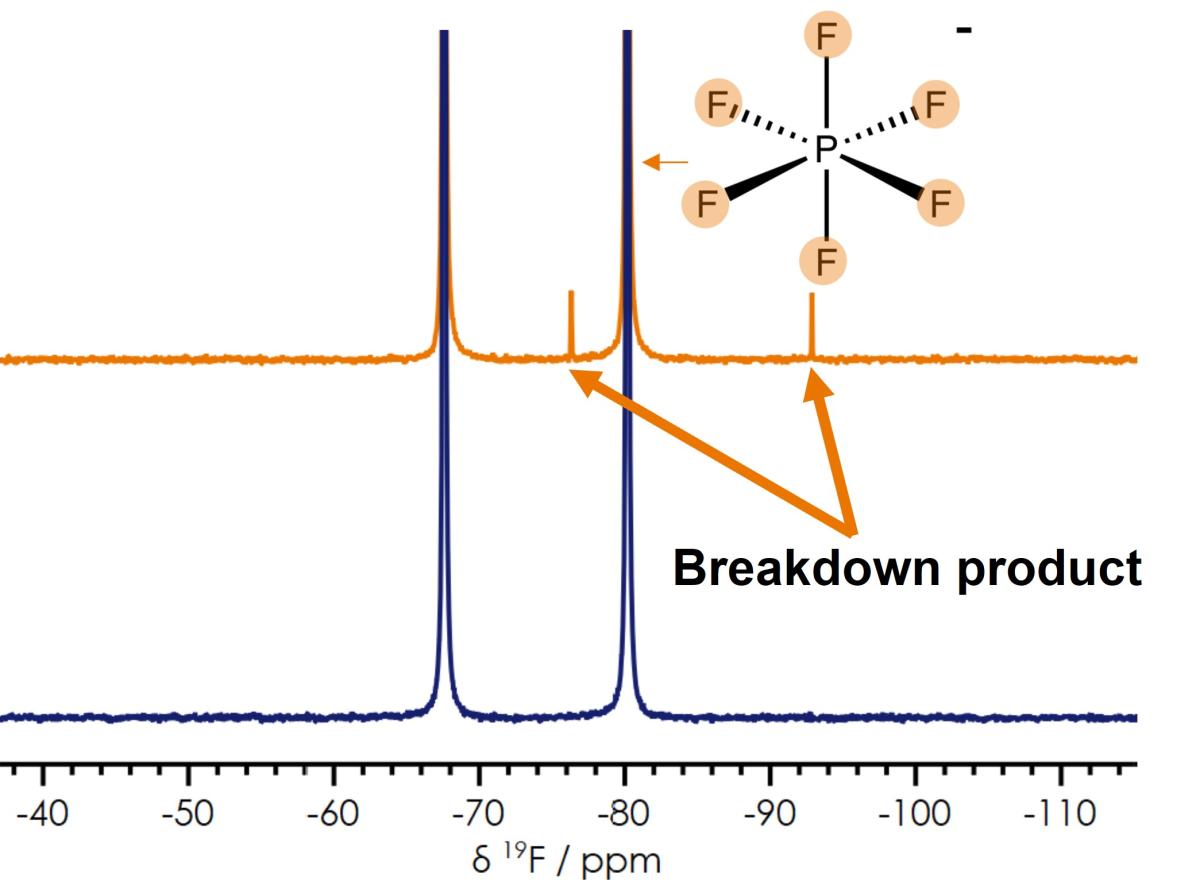

Lithium battery electrolyte breakdown products (Difluorophosphoric acid from the presence of unwanted water) identified from the Fluorine NMR spectrum

There are many exciting battery electrolyte innovations being worked on. Based on some of the presentations and discussions at this year electrolyte symposium, I believe the following three are amongst those that will be important for the success of next generation batteries: