Products

Applications

Learning

Time Domain NMR, also known as NMR relaxometry or TD-NMR, is applied for quality control and research across multiple industries. Systems are typically compact benchtop instruments, which most commonly measure oil, water, fluorine and for solid fat content determination in various samples. They are often automated for simplicity and throughput with tailored software and/or autosampler hardware, making them suitable for inline NMR applications. For several industries, systems are branded simply as analysers (e.g. solid fat analyser, oil seed analyser, spin finish fibre analyser). The technique is inherently quantitative, non-destructive for samples and often replaces less sustainable chemical extraction methods (e.g. Soxhlet).

Talk to our experts

Talk to our experts

A Nuclear Magnetic Resonance (NMR) signal is acquired by placing a sample with NMR active nuclei (typically ¹H) in a strong permanent magnet to produce magnetisation associated with those nuclei. One or more radiofrequency (RF) pulses, specific to the magnet field strength and nucleus being studied, are then applied to observe one or more signals in the time domain.

In contrast to NMR Spectroscopy (see “What is NMR Spectroscopy” for more details), time domain NMR uses a lower field strength and homogeneity magnet. Consequently, the time domain signal after the RF pulse (normally called the Free Induction Decay or FID) does not contain oscillations associated with the different chemical environments. Furthermore, rather than applying Fourier Transform (as done in NMR Spectroscopy) to a frequency spectrum for spectroscopy (left), the time domain signal may be analysed directly (right).

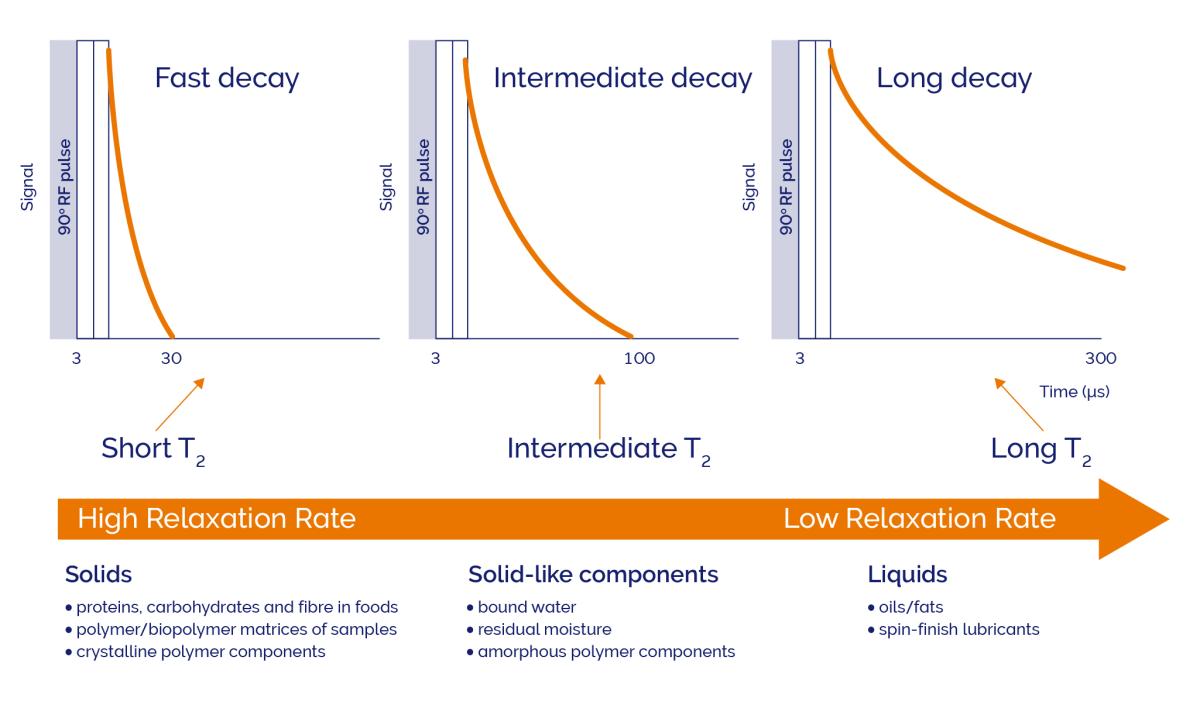

In the simplest interpretation, the time domain signal of Hydrogen (¹H), the most sensitive and abundant of NMR active nuclei, is comprised of a variety of components that differ by their decay rate (primarily described by the transverse (T2) relaxation time constant) reflecting the phase or state; solids decay rapidly, whereas liquids will take longer.

Thus, using the FID signal, it is possible to measure:

Applying another radiofrequency further separates, in time, the liquid signal from that of the solid and solid-like components; this is required for quantification. Thus, it is also possible to measure:

A practical example of TD-NMR analysis is the measurement of oil and water content in oilseeds according to the ISO 10565 method. Following the first RF pulse, the signal from both oil and water can be measured after the solid signal has decayed. A second pulse is applied to ensure that the oil signal can be measured after the signal from the ‘bound’ water (moisture < 10%) has also decayed, producing a Hahn echo. The water signal is determined from the difference between the two signals.

They are many reasons and advantages for measuring the time domain signal as opposed to the frequency domain (i.e. NMR spectroscopy):

1) The technique is non-invasive and non-destructive, so it measures samples ‘as-is’, without sample preparation, sometimes in their original, non-metallic, containers.

2) It can measure all the hydrogen signal from the sample, whether it is solid or liquid, regardless of its nature.*

3) The TD-NMR magnet does not need to have a high magnetic field strength or homogeneity and is lower cost compared to an NMR spectrometer.

*It is not possible to measure the signal immediately after the pulse, which means part of the solid signal is not directly measurable; this initial time period is called the dead time. However, the NMR signal may be extrapolated back to zero time, or the signal loss may be considered during the calibration process.

Some examples:

| Industry | Application |

| Food | Fat in snack foods, chocolate, milk/nutritional powders and other foodstuffs, Solid Fat Content (SFC), droplet size distributions in emulsions, Fat, Oil and Grease (FOG) from wastewater |

| Agriculture | Oil and moisture in oilseeds (ISO 10565) and their residues (ISO 10632), oil in dried olive paste, oil in dried palm mesocarp and more for optimising seed oil yield (for foods and biofuels) |

| Textile | Spin finish on fibre, also known as Oil Pick-Up (OPU), Finish on Yarn (FoY), lubricant and avivage, fluorinated and elastomeric coatings, lotion on fabric |

| Petroleum | Hydrogen content in distillates (ASTM D7171) and sustainable fuels, wax content in petroleum products and oil content in waxes |

| Polymers | Xylene solubles in polypropylene, plasticiser in PVC, polymer density & crystallinity, oil in rubber and fluorine content |

| Pharmaceuticals | Fluoride content in toothpaste, fluorinated active ingredients and moisture in tablets |

| Other | Fluorine in powders (e.g. fluorspar, alumina) and limestone filler in asphalt |

In summary, TD-NMR is a powerful non-destructive and quantitative method for material content measurement, without need for sample preparation. Instruments can be used with minimal operator training in almost any environment.