Products

Applications

Learning

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

How does Nuclear Magnetic Resonance (NMR) increase the accuracy and speed of Fat, Oils and Grease measurement to help avoid the build-up of contaminants? And can we automate the sample process entirely?

Chewing the fat

In 2017, people around the world marvelled at – and were disgusted by – the famous 130 tonne ‘fatberg’ of London – weighing the same as 11 double decker buses and stretching the length of two football pitches – which garnered international headlines. It was a graphic illustration of exactly how much fat can build up right under our feet.

However, even minuscule amounts of Fat, Oils and Grease (FOG) released in waste water can add to an existing fatberg with the potential to cause overflows that can release more hazardous materials into the environment. Therefore, measuring the levels of FOG is crucial to environmental monitoring performed by water suppliers and environmental authorities. Not only does it encourage industrial and commercial sites to be more responsible about what is released in their waste water, it also helps prevent the build up of blockages such as the infamous fatberg.

Typically, laboratories analyse the waste water by first passing a large volume through a glass filter of a particular pore size to collect particulates, then selectively determining the grease build-up on the dried filter using solvent extraction techniques. The problem with this approach is that it is time-consuming, taking up to two hours to complete. It also requires highly skilled technicians and so is prone to human error and thus erratic results. Furthermore, it depends on the use of dangerous materials, which are difficult and expensive to dispose of safely.

Faster, cleaner, safer

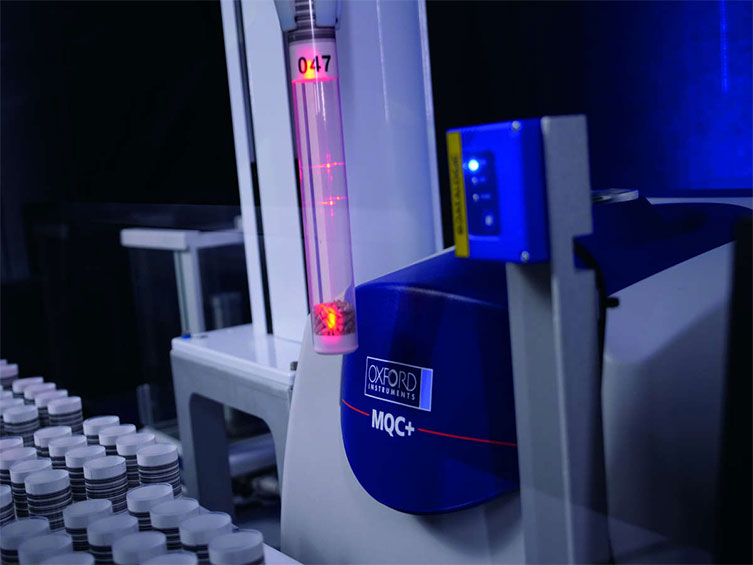

In contrast, the Oxford Instruments MQC+ benchtop Nuclear Magnetic Resonance (NMR) analyser provides a smart alternative to such extensive wet-chemistry methods. It is quick and easy to perform, simple to calibrate and requires minimal sample preparation, making it ideal for non-specialist laboratory personnel.

Using the MQC+ analyser couldn’t be simpler: take the glass filter through which the waste water has passed, evaporate off any moisture, then place in the analyser and get an instant reading. The analyser detects the signal from FOG on a single filter sheet after the initial NMR signals from the solids and any remaining moisture have decayed. The remaining signal intensity correlates with the mass of FOG in the sample – a more accurate reading than that provided by traditional methods.

The total measurement time takes five minutes start to finish with perhaps twenty minutes for conditioning beforehand. No specialist training is required and there are no hazardous and costly chemicals involved.

Automated productivity

There is one additional benefit to introducing MQC+ to your analytical portfolio. Not only is it faster, more accurate and less expensive to use, you can also automate the entire process using MQ-Auto.

Why MQC+?

NMR is a clean, fast, reliable and user-friendly technique for the analysis of FOG from waste water. It provides a more effective way of getting the results you need in minutes rather than hours while requiring little training.

If you need to monitor the FOG content of water, NMR will cut costs, increase operational efficiency, improve accuracy and make for a safer environment.

LEARN MORE ABOUT MQC+ LEARN MORE ABOUT FOG

To arrange a demo and see how our innovative measurement solutions could improve your operation, get in touch with a member of our expert team.