Products

Applications

Learning

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

The textile industry has come a long way in the last 200 years. Complex global supply chains now revolve around cutting edge manufacturing facilities that often produce a huge range of products. In such a high-volume environment, companies need to have an accurate idea of all the components going into their products. The slightest delay can trigger a painful increase in costs.

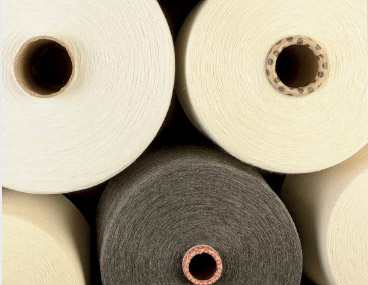

Having to halt production for long periods of time in order to accurately measure the spin finish level on incoming yarn that is used to make fabrics, is a problem for many in the textile industry. A busy manufacturing facility could need to measure many yarn samples each day.

As an innovative fabric manufacturer with an international reputation for brilliance, Heathcoat Fabrics knows the balancing act between keeping your operations ticking over while still ensuring you have a robust measurement regime in place. Founded in 1808, the company designs, develops, tests and delivers a wide variety of fabrics for a range of markets including automotive, aerospace, military and healthcare.

"Our approach uses in-house expertise and capability to find the right solution for our customers,"

Kamlesh Mistry, Heathcoat Fabric’s R&D Manager

“We have an incredible breadth of resources, including: yarn processing, warping, weaving, knitting, dyeing and finishing and a range of sophisticated chemical enhancements.”

Time-intensive and costly measurement

Heathcoat Fabric purchases the majority of its raw fibre from abroad before re-processing it at its facility in Devon, England.

The company needs to be able to accurately check there is sufficient spin finish on the incoming yarn. Too little spin finish and there is excessive friction and processing issues with the fibres. Too much and processing issues can arise through difficulty in scouring (cleaning) fabrics to emission issues, so the balance has to be right in having the correct amount of spin finish on the incoming yarn.

The testing process being used before the company adopted the Oxford Instruments MQC analyser was incredibly timeconsuming. Using the traditional soxhlet method involving the removal of oil from the yarn took the company three hours to perform, and also created costs around the purchase and lawful disposal of harmful solvent.

This wasn’t an optimum solution for a company working in an incredibly cost-sensitive industry. By using Nuclear Magnetic Resonance (NMR) instead of traditional wet chemistry methods, Heathcoat Fabrics could speed up their measurements while eliminating the need to use harmful solvents.

Injecting efficiency with MQC

Oxford Instruments’ MQC is a benchtop NMR analyser that can measure spin finish or oil pick-up on a wide variety of fibres. The instrument is designed to bring speed, accuracy, ease of use and reliability to fibre testing.

For Kamlesh Mistry, the adoption of MQC has had two clear operational advantages for Heathcoat Fabrics:

“Increased efficiency in the way the department works based around less time being spent on getting results and being able to focus on other areas,” he said. “The cost reduction in terms of not using any solvents is also a big benefit for us.”

By using MQC, the company has cut its quality control time from hours, with the analyser producing accurate results in 10 minutes. This means that quality checks on incoming yarns no longer need to be an invasive part of the manufacture process. This is especially true when the minimal user training required to operate the machine is factored in. After unpacking and an initial period to warm up and stabilise, a small amount of time setting up calibration, samples are simply inserted into the MQC for measurement.

The fact that the MQC can be applied to a variety of coatings besides oil also means that it is capable of evolving alongside the company’s operations. This means that Heathcoat Fabrics is not constrained by its choice of equipment. Rather, it can continue to do what it has done since its founding: create brilliant and high-quality products for its international client base.

If you would like to speak to a member of our team about using the MQC for measuring spin finish and/or other coatings, or book a demo, get in touch today

Learn more about MQC+ Learn more about NMR and Textiles