Products

Applications

Learning

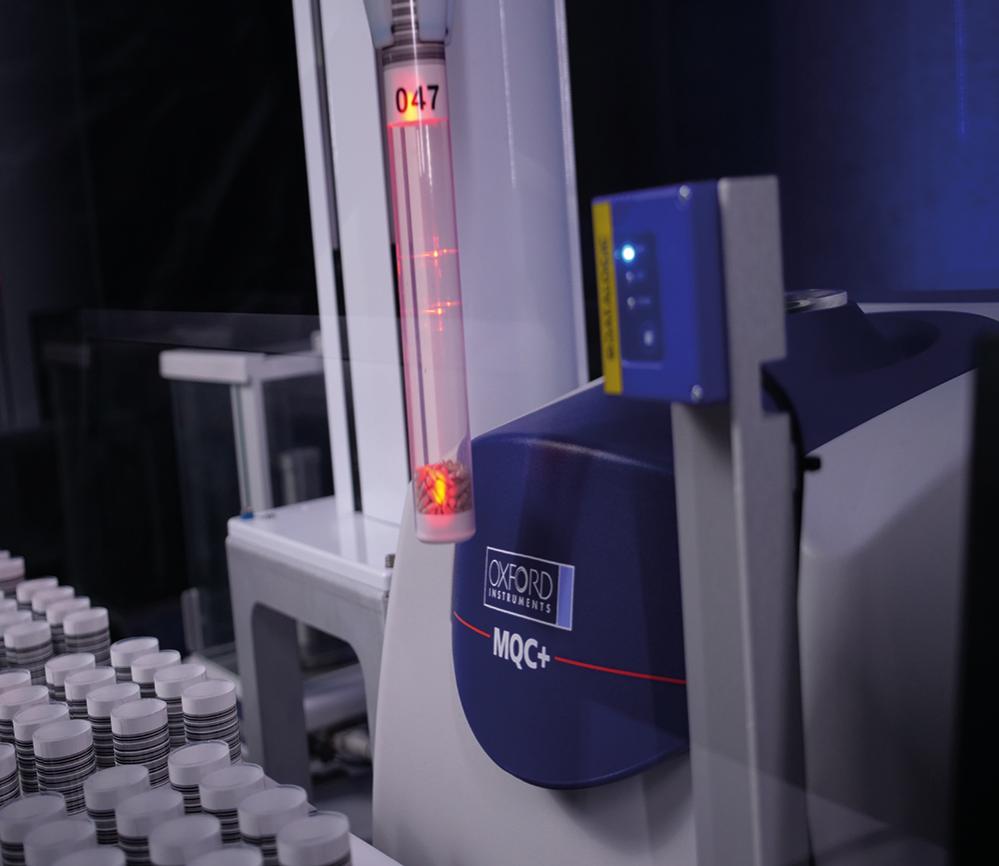

Thousands of users worldwide enjoy the fast and accurate measurements made possible by the MQC and MQC+ range of Nuclear Magnetic Resonance (NMR) analysers. Laboratory productivity and efficiency are given an extra boost with the MQ-Auto, a robotic system that extends the working time of the MQC+.

MQ-Auto is especially valuable for laboratories which require high throughput and/or high-performance applications which have relatively long measurement times, thus the technician can be relieved for other duties elsewhere.

Free up laboratory staff

Intuitive software requiring minimal training

Built-in comprehensive safety features

Very few user interventions required

Requires minimal user input, freeing up laboratory staff for more intensive tasks.

Measures up to 125 samples, 96 or 72 with conditioning dependent on probe size.

Different calibrations (and applications) may be loaded to the run list.

Compatible with both weighing and non-weighing methods, i.e. with and without a balance.

Both MQC+ and MQ-Auto are supported by Oxford Instruments trained engineers.

Two level security protection to ensure operator safety.

Choice of racks or block heaters as required by the application.

Robot can be paused, and door opened, during a run to add more samples; the racks may be removed for loading.

The MQ-Auto system is based around a high-performance robot arm and a range of sample racks and conditioning stations, defined by the application(s), as per the table below. A balance can be incorporated for applications that require samples to be weighed, and an optional barcode reader is also available for sample identification.

| Sample racks | 18mm (8ml) sample tubes | 26mm (14ml) sample tubes |

| Room temperature racks (maximum 4) | Maximum 50 per rack* | Maximum 32 per rack* |

| Heated blocks (maximum 4) | Maximum 24 per block* | Maximum 18 per block* |

*Three positions must be reserved for a tuning sample and initialisation routines

Operator safety is of course paramount with any electrical or mechanical installation, so comprehensive safety features have been built into the MQ-Auto. The robot arm itself is a so-called “collaborative robot”, designed to stop automatically if any obstruction (such as a human limb) is encountered in its path. In addition to this, the entire autosampler installation is housed in a transparent enclosure interlocked to shut down the robot arm if the door is opened. This two-level security protection ensures that the system can be operated safely with confidence.

The MQ-Auto is controlled by software running on either the Windows-10 internal computer of the MQC+ instrument or on an external PC. The software allows samples to be run against different calibrations, and also allows operation to be paused mid-run for additional samples to be added. Optional barcodes can be attached to sample tubes to identify the sample and to store the tare weight of the tube for measurements that require weighing.